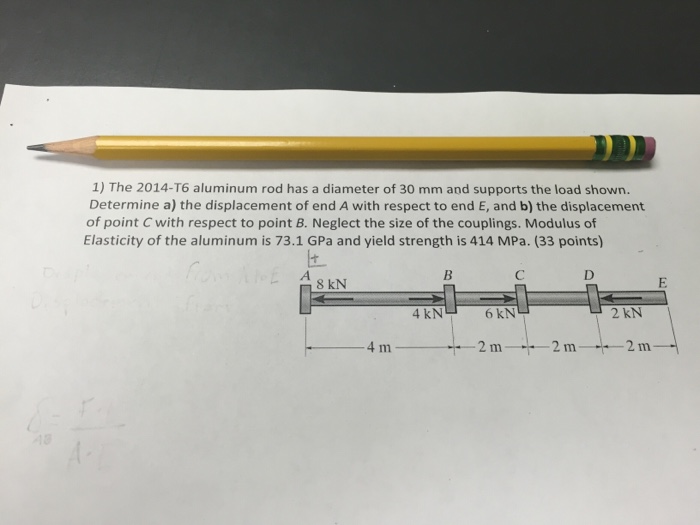

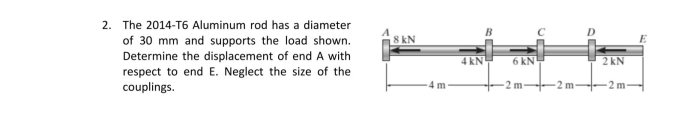

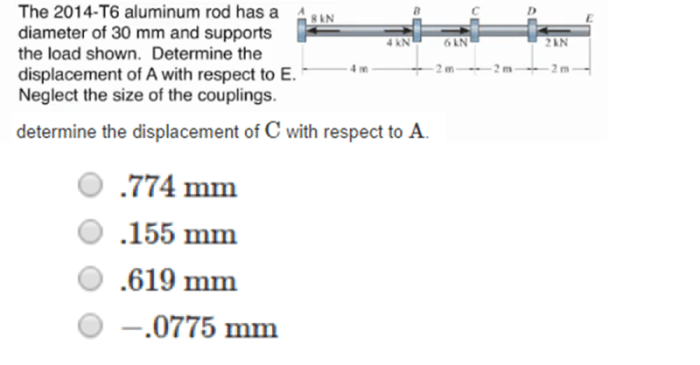

The 2014-t6 aluminum rod has a diameter of 30 mm – The 2014-T6 aluminum rod, with its diameter of 30 mm, stands as a versatile and widely used material in various industries. Its exceptional properties and adaptability make it a preferred choice for applications demanding strength, durability, and precision. This comprehensive exploration delves into the characteristics, applications, and design considerations of the 2014-T6 aluminum rod, providing valuable insights for engineers, designers, and professionals seeking to optimize its utilization.

The composition and mechanical properties of 2014-T6 aluminum, along with its dimensional tolerances and surface finish, are thoroughly examined. The significance of the 30 mm diameter is explored, highlighting its impact on the rod’s performance and suitability for specific applications.

Furthermore, the fabrication methods, heat treatment processes, and testing procedures are meticulously detailed, offering a comprehensive understanding of the rod’s production and quality control.

Material Properties

2014-T6 aluminum is a high-strength aluminum alloy known for its excellent mechanical properties and corrosion resistance. It is composed primarily of aluminum, with small additions of copper, magnesium, and silicon.

Composition and Characteristics

- Aluminum (Al): Primary constituent, providing strength and lightness.

- Copper (Cu): Enhances strength and hardness.

- Magnesium (Mg): Improves corrosion resistance and strength.

- Silicon (Si): Increases strength and reduces thermal expansion.

The T6 temper designation indicates that the aluminum has been solution heat treated and then artificially aged, resulting in a combination of high strength and toughness.

Mechanical Properties Comparison

| Property | 2014-T6 Aluminum | 6061-T6 Aluminum | 7075-T6 Aluminum |

|---|---|---|---|

| Tensile Strength (MPa) | 460-520 | 310-350 | 570-630 |

| Yield Strength (MPa) | 310-350 | 275-310 | 500-560 |

| Elongation (%) | 12-16 | 18-22 | 10-14 |

| Hardness (HV) | 120-130 | 95-105 | 150-160 |

Diameter and Dimensions

The 30 mm diameter of the aluminum rod is a significant dimension that determines its load-bearing capacity and rigidity. A larger diameter rod can withstand higher loads and bending moments.

Dimensional Tolerances and Surface Finish

The dimensional tolerances for the rod’s diameter and length are typically specified to ensure proper fit and performance in various applications. The surface finish of the rod is typically smooth and free of defects, which is important for preventing stress concentrations and fatigue failure.

Cross-Sectional Shape and Dimensions, The 2014-t6 aluminum rod has a diameter of 30 mm

| Dimension | Value |

|---|---|

| Diameter | 30 mm |

| Cross-sectional Shape | Circular |

Answers to Common Questions: The 2014-t6 Aluminum Rod Has A Diameter Of 30 Mm

What are the key advantages of using a 2014-T6 aluminum rod with a 30 mm diameter?

The 2014-T6 aluminum rod with a 30 mm diameter offers an array of advantages, including high strength-to-weight ratio, excellent corrosion resistance, good machinability, and weldability. Its dimensional stability and resistance to wear and tear further enhance its versatility and durability.

What are the typical applications of the 2014-T6 aluminum rod with a 30 mm diameter?

The 2014-T6 aluminum rod with a 30 mm diameter finds applications in various industries, including aerospace, automotive, manufacturing, and construction. It is commonly used in structural components, machine parts, shafts, and precision engineering applications.

How does the heat treatment process affect the properties of the 2014-T6 aluminum rod?

The heat treatment process, specifically the T6 temper, involves solution heat treatment followed by artificial aging. This process enhances the rod’s strength and hardness while maintaining its ductility and toughness. The T6 temper is commonly used to achieve optimal mechanical properties for demanding applications.